ADVERTISEMENT

Why Is It There? The Functional Reasons

- Pressure Regulation

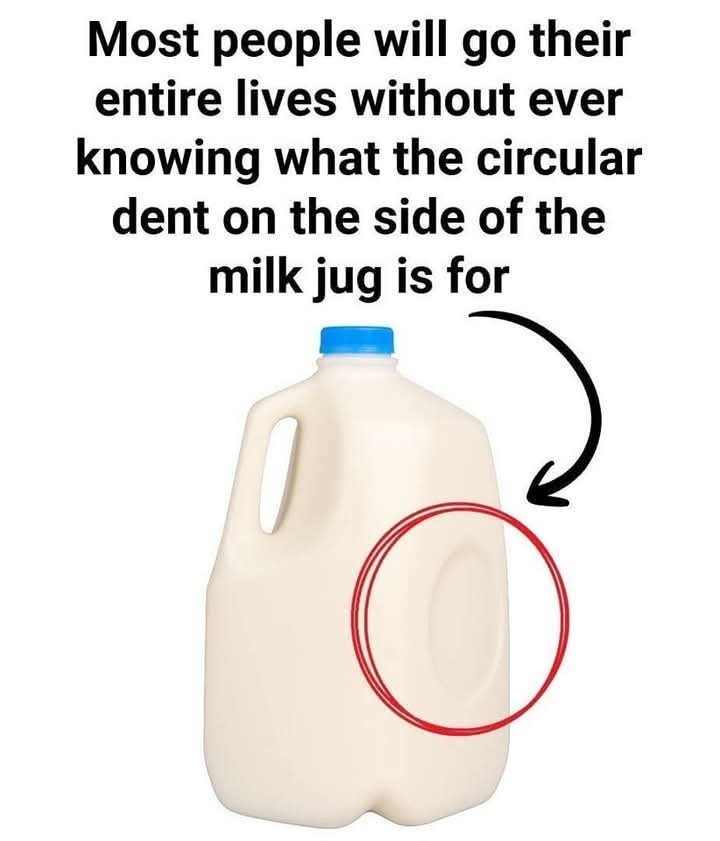

Milk jugs are typically made from thin, flexible plastic, which can easily deform due to changes in temperature or pressure. The circular dent helps to regulate internal pressure by allowing the jug’s walls to flex slightly without cracking or warping. This is especially useful when milk expands or contracts due to temperature fluctuations during transportation and storage. - Structural Stability

The dent acts as a reinforcing feature. By introducing a small, curved indentation, the jug’s surface gains added rigidity. This makes the jug more resistant to crushing or bending under pressure, whether it’s stacked on shelves or handled roughly during delivery. - Manufacturing Efficiency

From a production standpoint, the circular dent can help improve the molding process. It provides a reference point or structural cue during manufacturing, allowing for more consistent shaping of jugs. This reduces defects and waste, contributing to more cost-effective production. - Consumer Grip and Handling

Although not its primary purpose, the dent can also offer consumers a subtle tactile point for gripping the jug. This can make pouring easier and reduce accidental slips.

More Than Meets the Eye

Design features like the circular dent illustrate the intersection of engineering and everyday convenience. What seems like a minor detail is, in fact, a thoughtful response to real-world challenges — balancing material limitations, manufacturing constraints, and user experience.

Would you like me to tailor this article for a specific audience or format?

ADVERTISEMENT